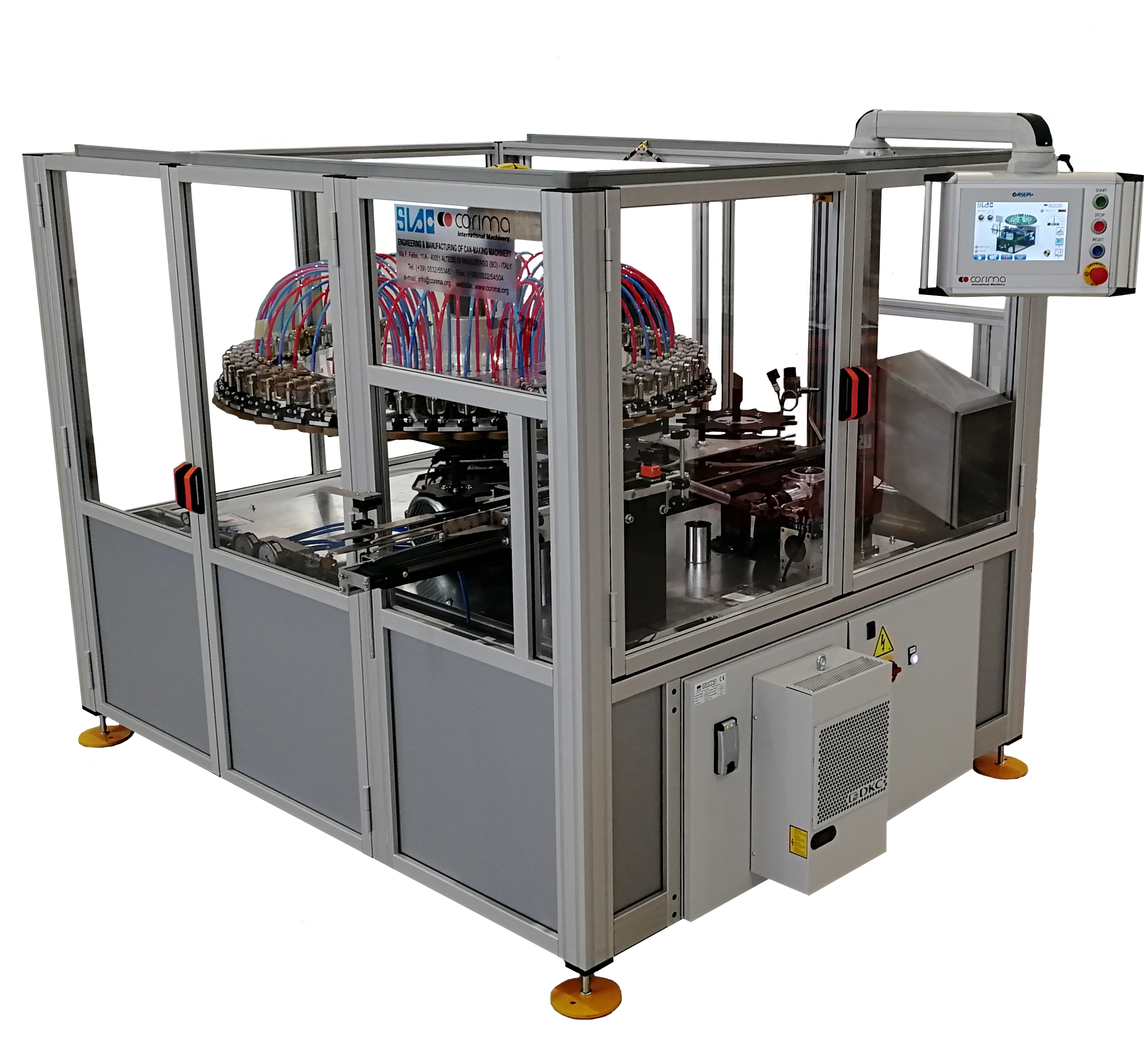

AUTOMATIC PLASTIC UNWRAPPER MACHINE

MODEL PLP-DB/07

Description:

This machine is used to automatically feed one or more seamers with unwrapped sticks of ends that were previously shrink-wrapped with plastic film.

The machine takes the sticks of ends from the hopper. An air-knife cuts the film longitudinally and it is then ejected into a collecting bag. After that, the expulsion device exerts a constant pressure to push the ends to the seamer.

This system increases production capacity and provides for a perfect cut of the film on both sides of the stick, avoiding any damage to the product and allowing a constant outflow of the ends.

The standard hopper assures 30 minutes’ autonomy of continuous production (of ø 73mm standard sanitary ends at 600 e.p.m.).

With the addition of a quick-changeover kit the machine can be adapted to precess sleeves wrapped in paper bags.

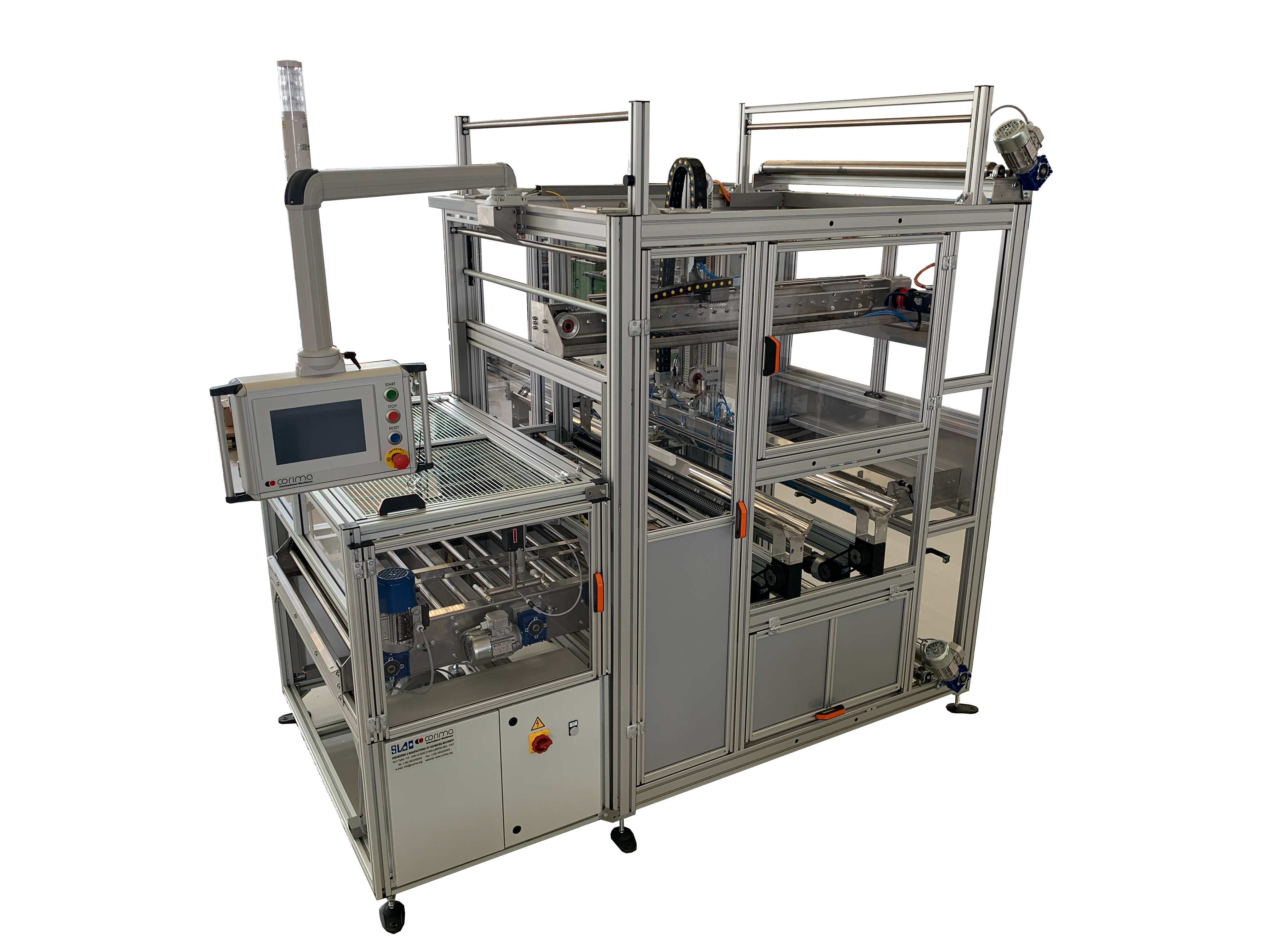

Corima International Machinery can supply a wide range of conveyors connecting the outlet of the unwrapper to the seamer to meet the customer’s specific requirements.

Optionals:

– Double hopper providing autonomy of 1 hour;

– Ergonomic hopper to make loading easier for the operator.

Technical data (standard):

END TYPE standard sanitary ends, easy open ends, aerosol bottoms and

domes, general line components

END DIMENSION ø 52 mm (200) to 153 mm (603)

STICK LENGTH from 250 mm to 800 mm

OUTPUT up to 5 rolls/minute

ELECTRICAL REQUIREMENTS 10 Kw, 380 V, 50 Hz, 3-phase + neutral wire

AIR CONSUMPTION 300 l/minute at 6 Bar

Upon request the machine can be customized according to customer specifications

“A network of companies with acquired experience and know-how”