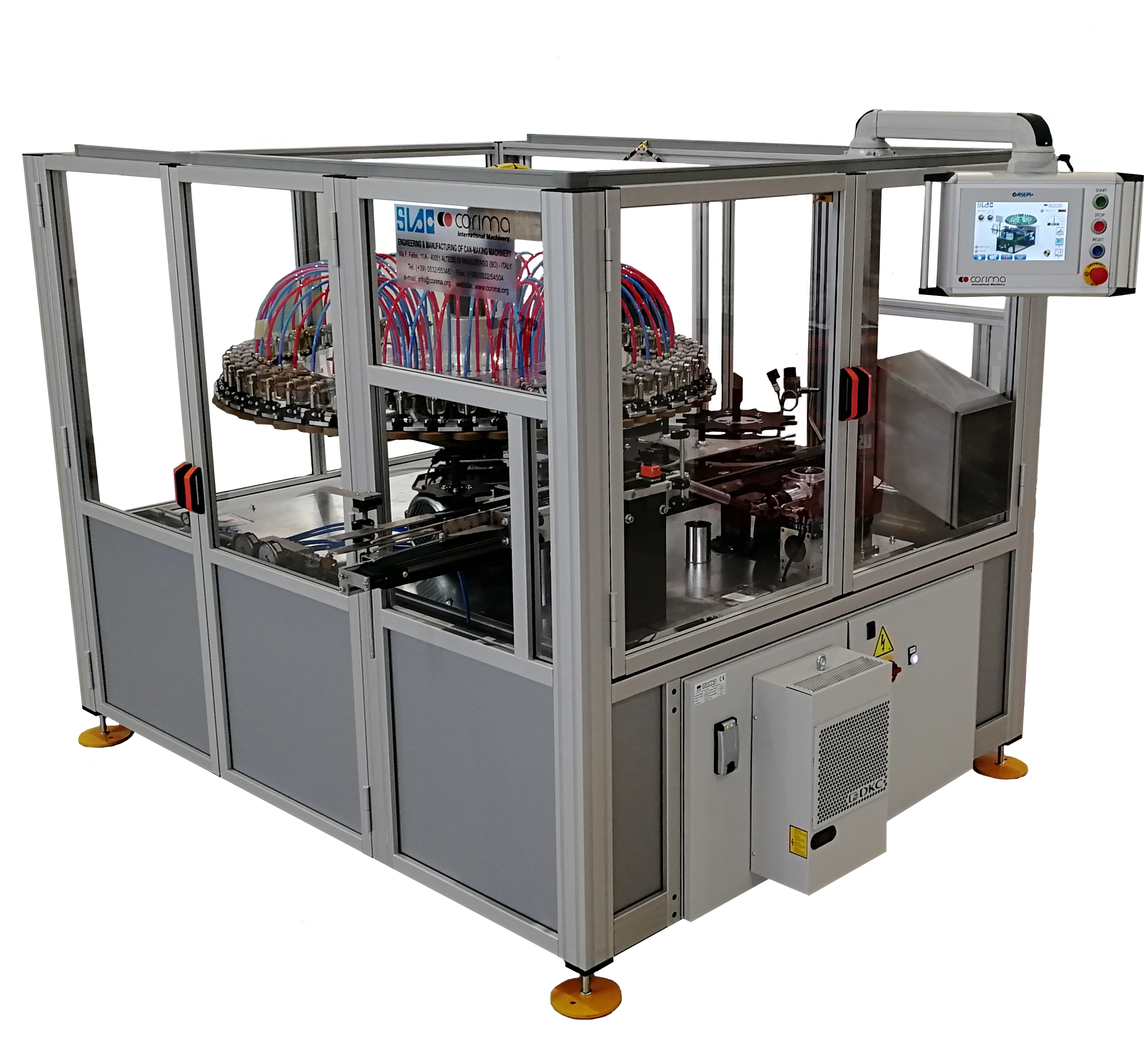

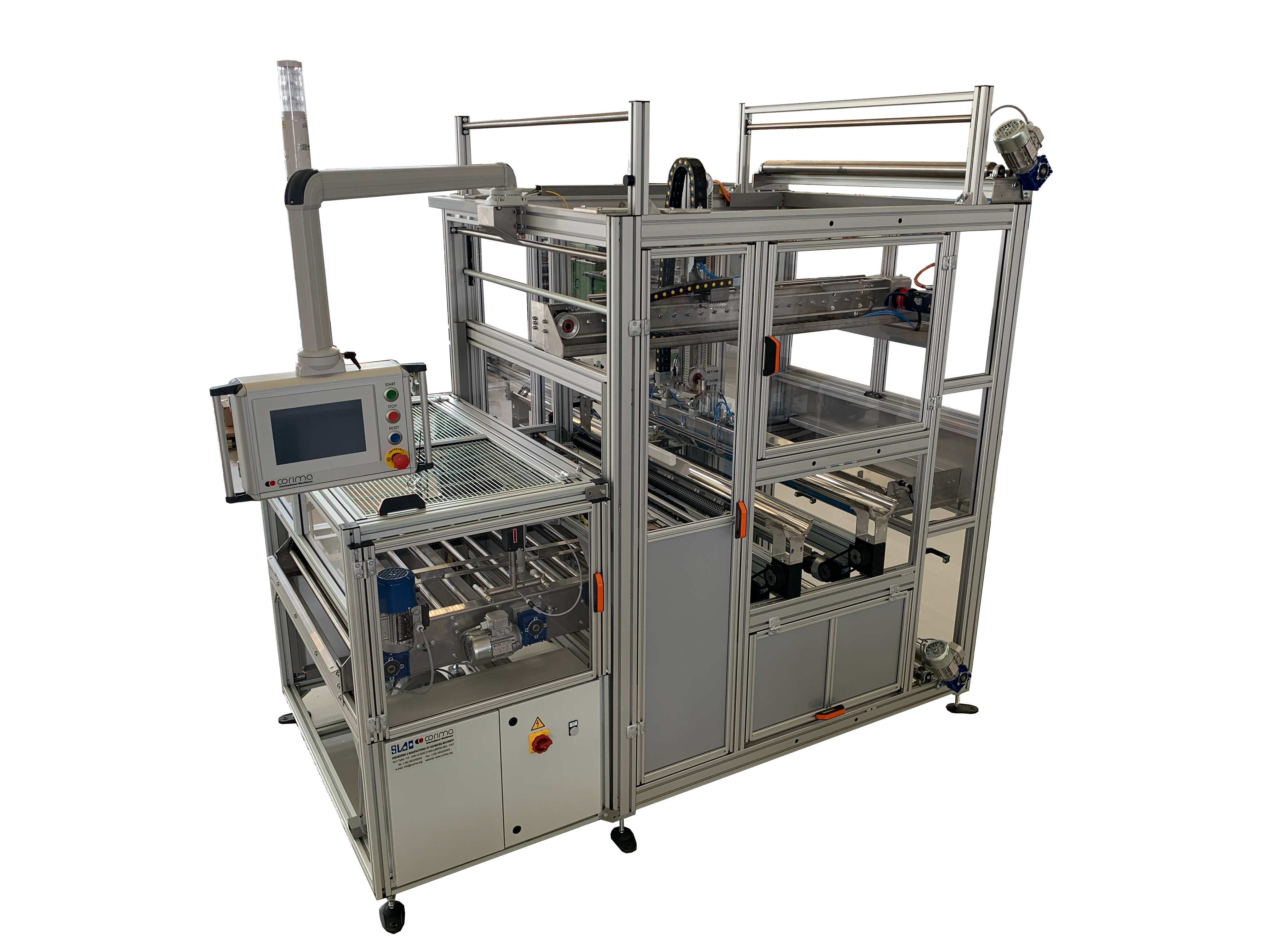

This machine has been developed to automatically shrink wrap steel ends.

The ends coming from the production lines are counted (accuracy ± 1 end per sleeve), separated into a stack and then picked up by a gripper. The gripper moves on a system of x-y axes and transports the stick to the wrapping station, where it is wrapped using micro-perforated plastic film, heat-sealed longitudinally and then heat shrunk by hot air blowers during transport through a step roller conveyor to the outfeed of the machine.

The machine can be tooled with one to 5 lanes and will conform to the required safety and accident prevention requirements.

Optional:

– Manual packing station with pre-made paper bags;

– Quality inspection station.

Technical data (standard):

END TYPE standard sanitary ends, easy open ends, aerosol bottoms and

domes, general line components

END DIMENSION ø 52 mm (200) to 153 mm (603)

STICK LENGTH from 250 mm to 800 mm

INFEED LANES from one to five

OUTPUT up to 7 rolls/minute

ELECTRICAL REQUIREMENTS 10 Kw, 380 V, 50 Hz, 3-phase + neutral wire

AIR CONSUMPTION 400-600 l/minute at 6 Bar (average)

Upon request the machine can be customized according to customer specifications

“A network of companies with acquired experience and know-how”