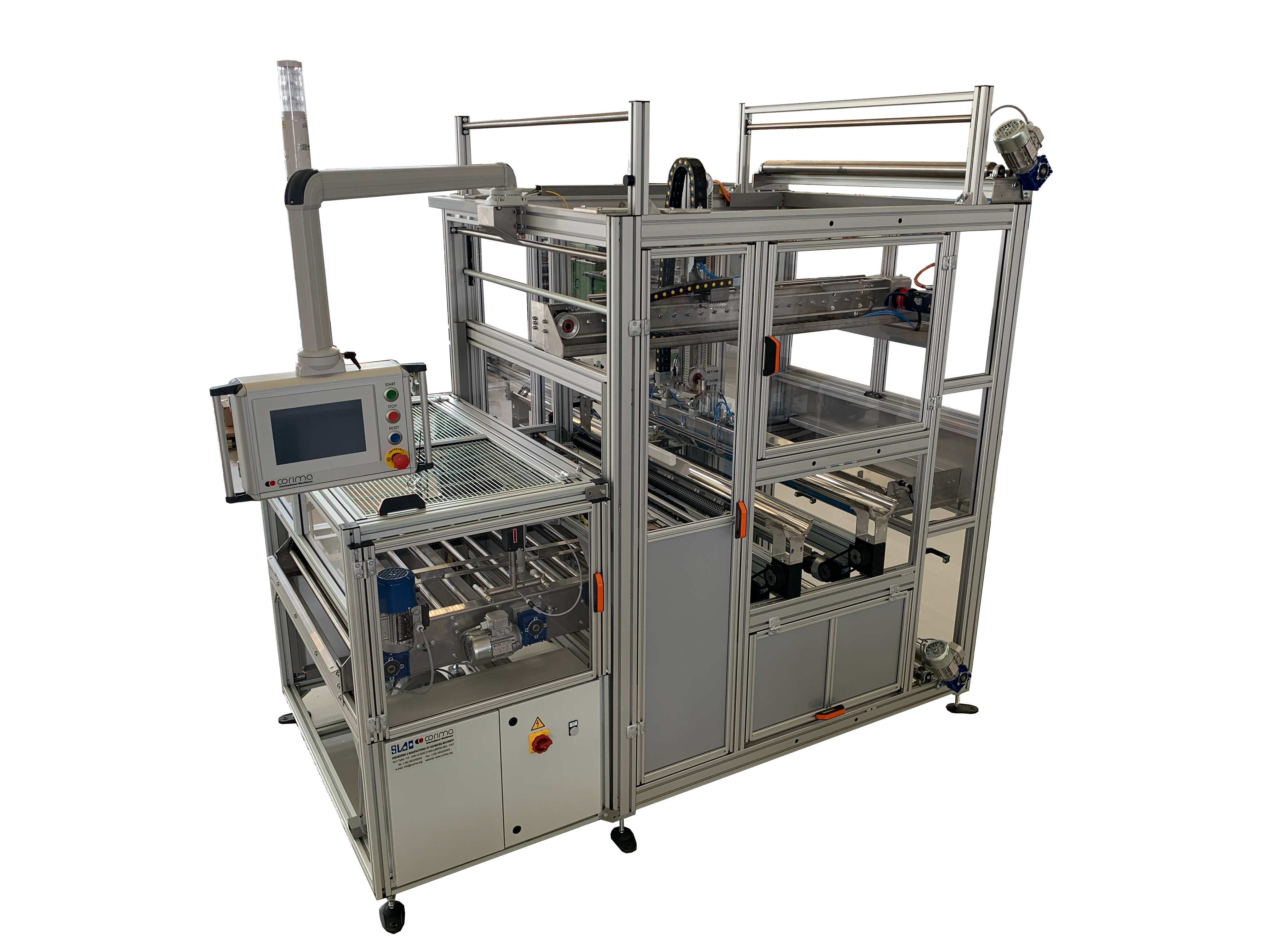

Automatic Plastic Wrapper

This machine has been developed to automatically shrink wrap steel ends.

The ends coming from the production lines are counted (accuracy ± 1 end per sleeve), separated into a stack and then picked up by a gripper. The gripper moves on a system of x-y axes and transports the stick to the wrapping station, where it is wrapped using micro-perforated plastic film, heat-sealed longitudinally and then heat shrunk by hot air blowers during transport through a step roller conveyor to the outfeed of the machine.

The machine can be tooled with one to 5 lanes and will conform to the required safety and accident prevention requirements.

The ends coming from the production lines are counted (accuracy ± 1 end per sleeve), separated into a stack and then picked up by a gripper. The gripper moves on a system of x-y axes and transports the stick to the wrapping station, where it is wrapped using micro-perforated plastic film, heat-sealed longitudinally and then heat shrunk by hot air blowers during transport through a step roller conveyor to the outfeed of the machine.

The machine can be tooled with one to 5 lanes and will conform to the required safety and accident prevention requirements.

Automatic Paper Bagger

This machine automatically collects, counts and puts the ends coming from one or more production lines into pre-made paper bags.

The paper bags are stored in a dedicated section with an autonomous capacity of 500 pieces. Here a special pneumatic arm takes the bags and places them in the bagging station where they are opened by means of an air blast before the stick of ends is pushed inside.

Once the ends are inside the bag, a mechanical device folds the paper edge.

The paper bags are stored in a dedicated section with an autonomous capacity of 500 pieces. Here a special pneumatic arm takes the bags and places them in the bagging station where they are opened by means of an air blast before the stick of ends is pushed inside.

Once the ends are inside the bag, a mechanical device folds the paper edge.

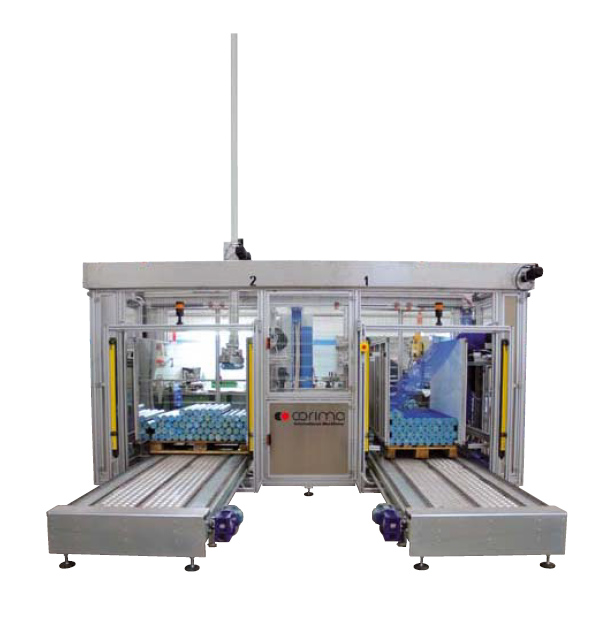

Dual Box Snake Wrap Palletizer

This machine has been developed by CORIMA to automatically palletize pre-made sleeves of ends applying a paper or plastic “snake wrap” between the layers to form a tight and secure pallet load.

The sleeves are carried by a conveyor into the machine. Here, the sleeves are picked up by the pick & place unit and placed on the pallet where the same unit handles the paper or plastic roll to form the desired snake pattern.

When the first pallet is completed, the p&p unit starts to form a new pallet load at the second work station while the first full pallet is transferred out of the machine by a motorized chain conveyor.

The sleeves are carried by a conveyor into the machine. Here, the sleeves are picked up by the pick & place unit and placed on the pallet where the same unit handles the paper or plastic roll to form the desired snake pattern.

When the first pallet is completed, the p&p unit starts to form a new pallet load at the second work station while the first full pallet is transferred out of the machine by a motorized chain conveyor.

Automatic Plastic Unwrapper

This machine is used to automatically feed one or more seamers with unwrapped sticks of ends that were previously shrink-wrapped with plastic film.

The machine takes the sticks of ends from the hopper. An air-knife cuts the film longitudinally and it is then ejected into a collecting bag. After that, the expulsion device exerts a constant pressure to push the ends to the seamer.

This system increases production capacity and provides for a perfect cut of the film on both sides of the stick, avoiding any damage to the product and allowing a constant outflow of the ends.

The machine takes the sticks of ends from the hopper. An air-knife cuts the film longitudinally and it is then ejected into a collecting bag. After that, the expulsion device exerts a constant pressure to push the ends to the seamer.

This system increases production capacity and provides for a perfect cut of the film on both sides of the stick, avoiding any damage to the product and allowing a constant outflow of the ends.

“A network of companies with acquired experience and know-how”

Our Group